Discover how ToffeeX was used by Ricoh to design an advanced heat sink that was optimized to be 31% more efficient than a conventional design in dissipating heat from the CPU.

The heat sink was designed to take advantage of Ricoh’s unique Aluminium Binder Jetting process. It shows how the combination of advanced physics-driven generative design software and innovative manufacturing processes can be a key enabler in supporting electrification across different industries.

The advanced heat sink project

As companies worldwide transition to cleaner energy sources, Ricoh is also moving towards electrification to lower CO2 emissions and promote a greener society. However, electrification presents thermal management challenges for electronic components. These components fail when temperatures exceed their standard operational limits. Efficient cooling systems are, therefore, a necessity.

A heat sink is a device used to dissipate heat from electronic components. It works primarily through conduction – to extract heat from the source – and convection to transfer the heat to the fluid medium and away from the device.

Convection can be either natural (airflow caused by temperature and fluid density differences) or forced (e.g., using a fan to push the air through). This distinction defines two types of heat sinks: passive and active. A passive heatsink has no moving parts, while an active heat sink uses a fan or a pump to force more fluid to pass through it, thus increasing the cooling efficiency.

Extruded heat sinks are popular for dissipating heat from electronic components due to their cost-effectiveness and efficient thermal performance. Their design represents the “state of the art” engineers have developed over the years to maximize the surface area and effectively drive the thermal energy away from the CPU, thus preventing overheating and ensuring optimal performance. The manufacturing process for extruded heat sinks allows for cost-efficient production, making them a practical and economical solution for thermal management in electronics. While extruded heat sinks are effective, standard, off-the-shelf designs, engineers always strive to design more efficient devices to enhance heat transfer through geometry modification.

Can we design something better?

Additive Manufacturing = Design Freedom

Additive Manufacturing has significantly expanded the boundaries of engineering design. Engineers can now design shapes that were previously impossible to manufacture, even with the most advanced 5-axis CNC machines.

To improve heat transfer, triply periodic minimal surfaces (TPMS) have become a common solution for 3D printed designs. TPMS offer a high surface area to volume ratios; the higher the surface area, the more effective the heat transfer.

However, these structures are not always the most efficient solution when considering the design’s overall performance, particularly for forced convection heat sinks. In fact, there’s a downside to this beautiful intricate shape: higher pressure losses.

Aluminium Binder Jetting by Ricoch

In the landscape of Additive Manufacturing, RICOH recently developed an innovative Aluminium Binder Jetting process. A unique aspect of this process is the capability to print without support structures traditionally used to sustain overhanging regions in metal Laser-Based AM processes, providing designers with even more freedom and flexibility.

However, traditional CAD and DfAM software can’t always fully exploit Ricoh’s process’s potential. These tools typically limit users to only fill—or better infill—predefined geometrical envelopes with different lattice types, such as the TPMS mentioned above. They require expertise in computational fluid dynamics and thermal management as well as an understanding of design rules specific to AM, which can be a barrier for many engineers.

While Ricoh’s unique process clearly offers freedom, traditional CAD or Design for Additive Manufacturing (DfAM) software often fails to realize it fully. These tools can generate complex shapes, but they are limited by the complexity that the human mind can conceive and their design skills!

Furthermore, these approaches still necessitate numerous iterations between design and simulation, demanding considerable human invention and expertise in several engineering fields.

For example, a designer looking to create a novel heat exchanger for Additive Manufacturing should have a good knowledge of computational fluid dynamics and thermal management and an understanding of design rules specific to the printing process, which can be a barrier for many engineers. This process not only limits the potential of the designs but also increases the time and effort required in the design phase.

This is where ToffeeX comes in.

Physics-Driven Generative Designs with ToffeeX

ToffeeX is a revolutionary physics-driven generative design software that empowers engineers to create high-performant designs faster and more efficiently by automating the design process using advanced algorithms and optimization techniques.

Key Features of ToffeeX

- Multi-Objective Optimization: ToffeeX can optimize for multiple objectives simultaneously. Whether you are looking to reduce pressure losses or maximize thermal performance, with ToffeeX, you can design for different performance parameters at the same time, to meet all your requirements.

- Fast Turnaround: Traditional design processes can be time-consuming. ToffeeX delivers optimized designs in a matter of hours, significantly accelerating the development cycle.

- Simplified Workflow: ToffeeX requires minimal user input and doesn’t necessitate expertise in CFD. Whether optimizing heat sinks, manifolds, heat exchangers, or mixers, to name some examples, users don’t need to be experts in fluid dynamics or thermal management; they simply need to set their design goals and let the physics design for them.

Using ToffeeX, we are accelerating our design cycle and creating more efficient heat sinks. It only takes us a few weeks to go from the initial concept to manufacturing our design.

Masato Tsuji, Mechanical Designer, Ricoh

From the idea to the final product in ToffeeX

Unlike traditional CAD and DfAM software, ToffeeX does not rely on human ingenuity to conceive complex shapes. Instead, it leverages the laws of physics and advanced optimization algorithms to explore possibilities beyond standard designs.

ToffeeX eliminates the need for multiple iterations between design and simulation, thus saving time and reducing the need for human expertise.

ToffeeX only requires a few inputs from the users:

- A Design Domain, i.e., the volume inside which the software can design an optimized component;

- A set of Boundary Conditions to describe the physical phenomena involved during the optimization;

- One or more “Optimization Objectives” are used to define the goals of the design process.

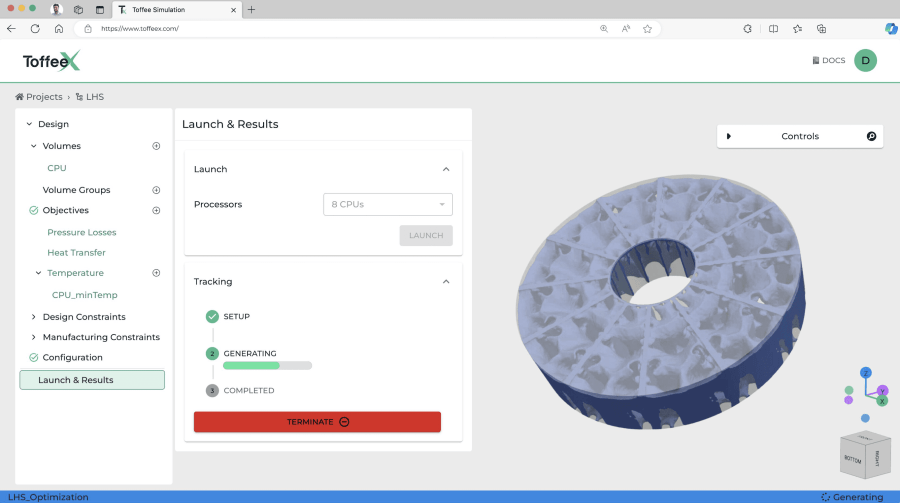

Setting up the design optimization problem quickly is possible with a few simple steps. For Ricoh’s active heat sink design, we set the Optimization Objectives as “Minimization of Pressure Loss” and “Minimization of Temperature of the CPU.”

With a simple interface, users can easily define all the necessary Boundary Conditions and parameters to run the optimization study. There’s no need to be an expert in CFD!

Results

The air-cooled heat sink generated using ToffeeX proved 31% more efficient than the conventional extruded design.

With its multi-objective optimization capabilities, ToffeeX allows users to create designs that can adapt to any requirements, whether extracting more heat or saving energy by minimizing losses.

Exploring different design solutions simply involves tuning the relative importance of one optimization target compared to the other, along with other meaningful design constraints.

Ricoh tested four different parameter combinations for this advanced heat sink before selecting the result that satisfied all their requirements. With each design iteration taking approximately 1 hour and 30 minutes, it took less than 7 hours of computational time and no more than 30 minutes of actual engineering time to go from an empty space to a ready-to-print geometry.

Conclusion

By leveraging ToffeeX, Ricoh engineers significantly improved their advanced heat sink design process. The software helped them leverage their Aluminium Binder Jetting process to manufacture an optimized heat sink design that achieved a remarkable 31% improvement in thermal efficiency compared to traditional extruded heat sinks.

Ricoh’s story exemplifies the transformative power of generative design in engineering. ToffeeX empowers engineers to create highly efficient, manufacturable designs faster than ever before. This optimizes performance and device longevity and contributes to a greener future by enabling advancements in electrification across various industries.

While Design for Manufacturing, whether traditional or Additive, requires users’ expertise and understanding of design rules as well as Fluid Dynamics and Thermal Management, ToffeeX does not.

Just set your goals and let the physics design it.

About RICOH

Ricoh is a Japanese multinational imaging and electronics company. It offers a comprehensive suite of services, including cutting-edge digital tools, information management solutions, and Additive Manufacturing capabilities.