Introduction

Sometimes, optimizing just one part of a system can lead to significant benefits for the entire setup.

This case study shows how ToffeeX was used to redesign and optimize a shell-and-tube heat exchanger header. Using a design from the Università di Parma’s biomass gasification plant as a reference, the goal was to boost heat exchanger efficiency. The targeted redesign of the heat exchanger header not only improved overall system efficiency but also reduced maintenance issues caused by tar buildup.

Background

As the world seeks greener alternatives to fossil fuels, biomass has emerged as a promising renewable energy source. Biomass gasification is a renewable energy technology that converts organic materials into syngas – a mixture of combustible gases like hydrogen, carbon monoxide, and methane. Syngas can fuel cogeneration systems such as gas turbines for both electricity and heat generation.

However, the gasification process also produces undesirable byproducts such as tar, a complex mixture of organic compounds that can condense and cause fouling and clogging. Effective tar removal is crucial to prevent operational issues and maintain system efficiency.

Traditional methods like wet scrubbing can be inefficient and lead to additional challenges, such as wastewater treatment and energy losses. Using heat exchangers to cool syngas and promote tar condensation offers an alternative solution but introduces the risk of tar deposition on heat transfer surfaces due to the tar particles condensing when local temperatures fall to the dew point.

Application

- Based on a commercial-grade system for the gasification of wood chips, located on the Università di Parma campus, which utilizes waste products as feedstocks and recovers heat by warming up water for the site.

- Enhancing the efficiency of syngas cooling and tar condensation further minimizes emissions and environmental impact associated with biomass gasification.

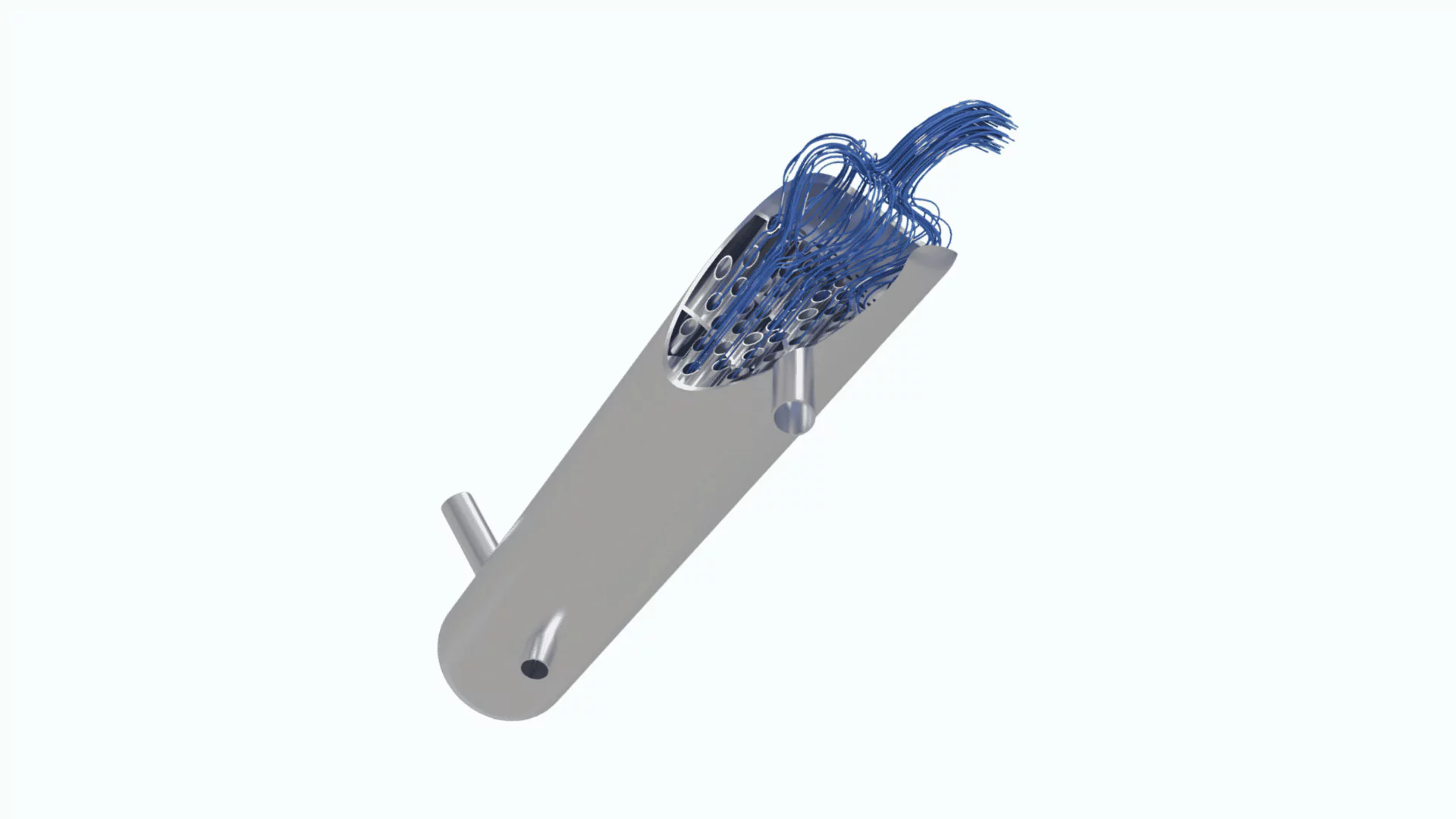

- The diagram on the right shows an example layout of a syngas heat exchanger which is similar to the one used by the University.

- Challenge: Significant non-uniform flow distribution in the syngas inlet header causing some tubes to receive higher flow rates while others having significantly lower flow, leading to uneven heat transfer and cooling, causing tar deposition and clogging in some tubes.

- ToffeeX generative design software was used to improve the flow distribution and thereby the overall heat exchanger efficiency.

Results – Superior Heat Exchanger Efficiency

- Overall system heat transfer increase of 12%. Optimizing an inexpensive part to benefit the whole system of the heat exchanger efficiency.

- Velocity deviation reduced by 92%.

- Reduction tar deposition & maintenance – The reduction of dead zones and flow recirculation areas decreases the risk of tar accumulation in the exchanger’s lower regions, leading to more efficient cooling and a lower risk of engine damage due to tar reaching the combustion stage.

The design optimization was run using overhang control for the additive manufacturing processes, with a maximum allowable overhang of 45 degrees. This refinement reduced the need for extensive support structures during printing, minimizing material usage and post-processing time. By optimizing the design for smoother overhangs, the process achieves more efficient builds, improves surface quality, faster production times and lower overall manufacturing costs.

Even higher performance can be achieved without overhang control, lowering the pressure drop to 275 Pa, while further decreasing the flow deviation between the tube to under 93% of the baseline. All while keeping a similar heat transfer performance. However, the design without overhang control is inherently harder to manufacture – therefore the design with overhang control was selected.

Why ToffeeX?

- Advanced Simulation Capabilities: ToffeeX enables users to customize fluid properties and material characteristics for optimized outcomes tailored to specific applications.

- Powerful Optimization Tools: Tools like Velocity Target allow you to specify relevant objective constraints.

- Manufacturing Flexibility: With options for both additive and conventional manufacturing, ToffeeX supports diverse production requirements, including overhang control to streamline manufacturing.

- User-Friendly Interface: The intuitive design allows for easy integration into existing workflows.

- Accelerate time to market: By meeting critical manufacturing and performance needs, ToffeeX drives efficiency gains and reduces production bottlenecks, accelerating time to market.