Challenge & Opportunity

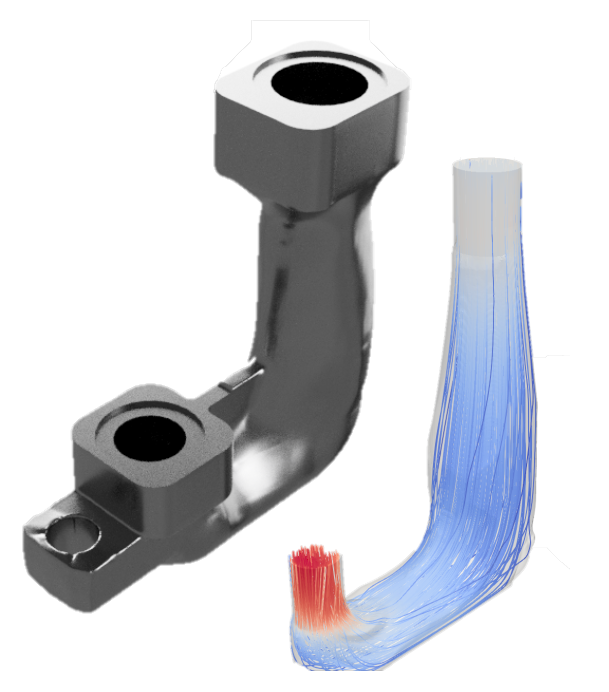

Heavy-duty machines used in construction, mining, or forestry require robust and efficient hydraulic systems for durable performance. One of the most important coupling designs for hydraulic systems is a U-bend.

These components must reverse the direction and thus the momentum of the hydraulic fluid. According to Newton’s second law, this significant change in momentum requires a substantial pressure force acting on the fluid, resulting in a significant pressure loss across the system. These inefficiencies are magnified when the U-bend also induces inefficient fluid flow structures such as turbulence, velocity gradients, or recirculation regions

Using ToffeeX’s physics-driven generative design tools, the team set out to explore new designs for a hydraulic U-bend to increase the efficiency of hydraulic systems for heavy machinery.

Approach

The process began by importing the existing baseline geometry for the U-bend and defining a design domain for the internal fluid passage. The target conditions were 150 L/min volumetric flow for a common hydraulic fluid with a density of ~916 kg/m³ and a kinematic viscosity of ~36×10⁻⁵ m²/s.

The design objective for the design cycle was to minimize the pressure losses across the system while also targeting a specific mass.

At the same time, additive manufacturing constraints were enforced, specifically a minimum feature size and overhang angle minimization requirement.

By generating several design options using ToffeeX, engineers were able to generate a smooth internal geometry for the U-bend.

The new design has fewer abrupt transitions and sharp edges, and produces an improved flow uniformity at the outlet as well as minimal dead zones in the velocity field. The new design generated by ToffeeX also includes several organically shaped flow turning vanes near the outlet of the U-bend.

Results

The design selected from the ToffeeX generative design outputs was evaluated using CFD simulation, showing:

Pressure Drop: A 25% reduction in the pressure drop across the component (from ~355kPa to ~260kPa).

Velocity Uniformity: A significantly improved level of velocity uniformity at the outlet of the component.

Reduced Mass: A 40% reduction in material usage in the optimized design.

Design Cycle: Initial design iterations could be run in 40 minutes each, allowing users to rapidly explore the design space available to them. During design exploration, more than 50 different designs were generated over two weeks to balance between the different requirements.

Impact and Next Steps

By achieving significant reductions in both pressure loss and material usage, SSAB and Komatsu have opened the door to lighter, more efficient hydraulic systems with improved lifecycle performance.

The optimised coupling is currently being validated for production scale-up in a heavy-duty environment.

Moving forward, further design iterations can integrate structural loads, fatigue life, and full-system interactions (e.g., fluid-structure multiphysics) and further refine manufacturability for batch production.

About SSAB

SSAB is a global steel company specializing in advanced high-strength steels and value-added services for demanding industrial applications. With production facilities in Sweden, Finland, and the United States, SSAB provides materials and engineering solutions that improve performance, reduce weight, and enhance sustainability across sectors including heavy machinery, automotive, construction, and energy. The company is known for its commitment to innovation, close customer collaboration, and industry-leading expertise in high-performance steel products.

About Komatsu

Komatsu is one of the world’s leading manufacturers of construction, mining, forestry, and industrial equipment. Founded in Japan and operating globally, Komatsu designs and builds machines and components engineered for durability, reliability, and productivity in the most challenging environments. The company integrates advanced hydraulics, automation, and digital technologies to support safer, more efficient, and more sustainable operations for customers worldwide.