Summary

Ricoh used ToffeeX to design an innovative cold plate for inverters in electric vehicle motor drives, achieving remarkable performance improvements through advanced optimization techniques. The project showcased the powerful combination of ToffeeX’s physics-driven generative design capabilities with Ricoh’s cutting-edge Aluminium Binder Jetting Technology.

The redesigned cold plate demonstrated exceptional results across multiple performance metrics:

- Enhanced thermal performance with a 6.9% lower thermal resistance

- Improved flow distribution resulting in a 31% reduction in pressure loss

- A significant 68% reduction in overall weight compared to the traditional copper design

This project’s success was achieved through an innovative hybrid manufacturing approach. This strategic combination delivered premium thermal performance while maintaining cost-effectiveness, combining conventional sheet metal processing for the base plate with additive manufacturing for the optimized core structure and die-casting for the housing cover.

The design process leveraged ToffeeX’s workflow to significantly reduce development time, eliminating the need for manual iterations between CAD and CFD tools. The final product was validated through physical testing, confirming the simulation predictions and demonstrating the practical viability of this innovative approach.

This case study exemplifies how next-generation design tools and advanced manufacturing techniques can revolutionize thermal management solutions for critical power electronic applications.

Introduction

Inverters are critical power electronic devices that convert direct current (DC) to alternating current (AC), playing a vital role in various applications, from renewable energy systems to electric vehicles. These devices generate significant heat during operation and thus require sophisticated thermal management solutions to maintain optimal performance and reliability in every condition.

The increasing power density demands of modern applications have pushed conventional cooling solutions to their limits, necessitating innovative approaches to thermal management.

This case study presents an optimized solution that addresses these challenges through ToffeeX’s advanced design capabilities combined with Ricoh’s Innovative Aluminium Binder Jetting Technology.

The application

This design challenge addresses a common problem in inverter heatsink design, focusing on maximizing heat dissipation while minimizing pressure drop and overall system weight. The figure below shows that the system features a cold plate where the inlet and outlet directly impinge on the base plate. A heat source is applied at the bottom, and pin-fin heatsinks are typically used to maximize surface area and improve heat transfer between the source and coolant.

Ricoh aimed to redesign the cold plate using ToffeeX to leverage thermo-fluid topology optimization for this application.

The design combines multiple manufacturing methods: the base plate is manufactured through sheet metal processing, the housing cover is manufactured through die casting, and the cold plate core is manufactured through additive manufacturing. The material selected is aluminium.

This approach combines cost-effective manufacturing methods with more advanced AM processes for optimal performance.

Design Process

ToffeeX is a physics-driven generative design software that enables engineers to create high-performance designs efficiently, combining CFD simulations and proprietary optimization techniques.

The software allows simultaneous optimization of multiple performance parameters—such as pressure loss reduction and thermal performance maximization—to meet specific requirements.

Ricoh focused on two key objectives in this project: reducing pressure drops and minimizing the cold plate’s thermal resistance. The team explored multiple design iterations, implementing symmetry constraints to leverage the original design’s symmetry.

The process generated a series of distinct design variations; three are reported in the picture below. ToffeeX produced these designs within hours, allowing engineers to compare and select the best-performing solution among a set of possible solutions.

This approach significantly reduced lead time by eliminating the need for manual iterations between CAD and CFD tools. The design process is schematically illustrated in the picture below.

Results

The thermal performance analysis showed significant improvements in the optimized design. Ricoh compared variants: the original copper design, an aluminium variation of the reference design, and the ToffeeX topology-optimized solution. The optimized design achieved better heat dissipation than the traditional design while reducing pressure loss by 2000 Pa.

Since copper has nearly twice the thermal conductivity of aluminium, the ToffeeX design achieved remarkable thermal performance compared to the reference design.

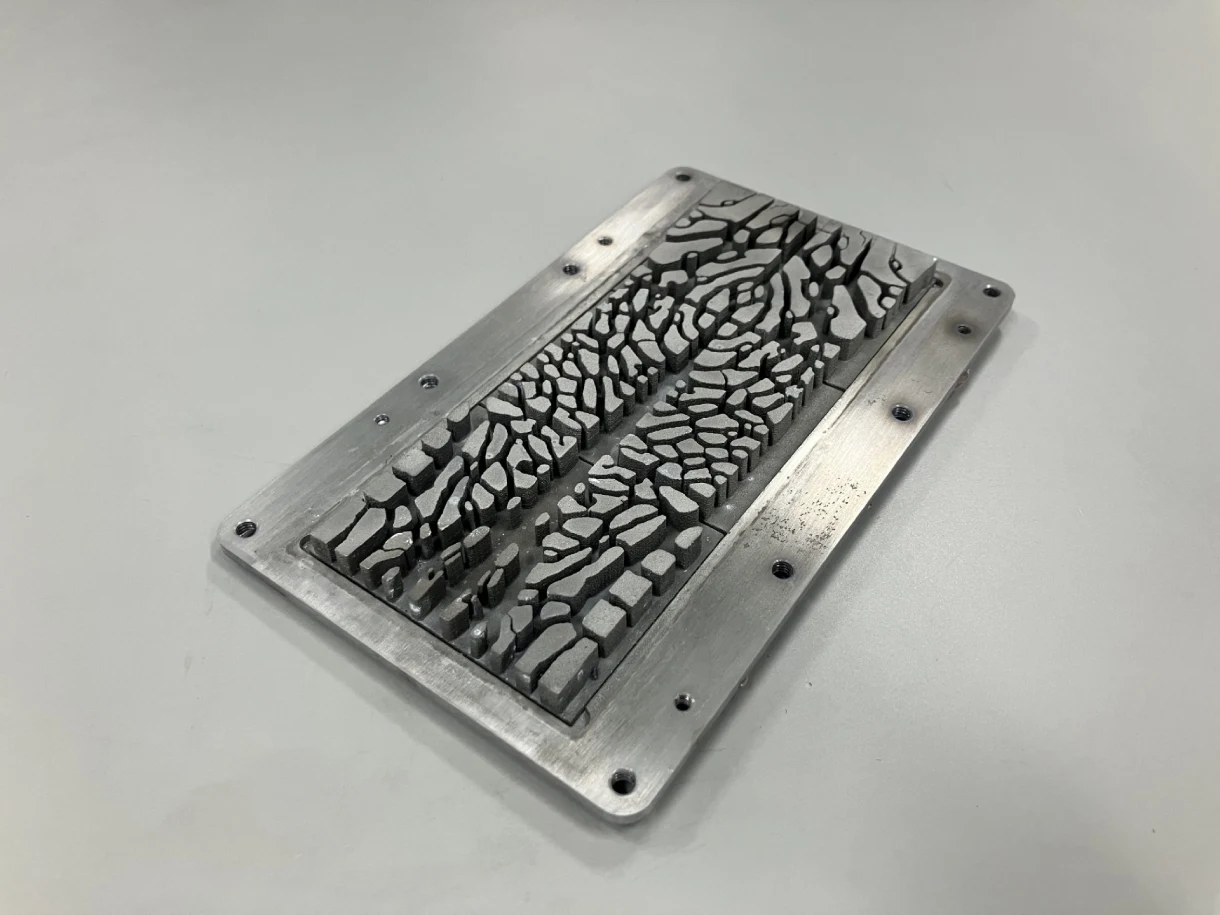

The physical validation was conducted using a custom test rig with precise temperature sensors and flow meters. The manufactured prototype, combining traditional manufactured parts with the additive manufactured optimized core structure, demonstrated excellent agreement with simulation predictions. The final product showcases the intricate internal geometry made possible through Ricoh’s advanced aluminium binder jetting technology.

Performance metrics from both simulations and physical testing demonstrate remarkable improvements:

- 68% reduction in overall weight compared to the copper design

- 6.9% lower thermal resistance compared to the copper design

- 31% reduction in pressure loss

This hybrid manufacturing approach represents a strategic balance between cost and performance.

The base plate, manufactured through conventional sheet metal processing, keeps production costs manageable for large, simple geometries. Meanwhile, the additively manufactured core structure enables complex internal channels and optimized heat transfer surfaces that would be impossible to achieve through traditional manufacturing methods.

This combination delivers premium thermal performance while maintaining reasonable production costs.

Conclusion

This case study demonstrates the significant advantages of using ToffeeX for thermal management design.

The software’s physics-driven generative design capabilities enabled rapid iteration and optimization, resulting in a cold plate that achieved remarkable improvements: 68% weight reduction, 6.9% lower thermal resistance, and 31% reduction in pressure loss compared to traditional designs.

ToffeeX’s ability to simultaneously optimize multiple performance parameters while considering manufacturing constraints proved invaluable in creating an innovative solution that balances performance, cost, and manufacturability.

The automated workflow significantly reduced design time by eliminating manual iterations between CAD and CFD tools, showcasing ToffeeX as a powerful tool for next-generation thermal management solutions.

About Ricoh

Ricoh, headquartered in Tokyo, Japan, is a globally recognized multinational conglomerate renowned for its diverse portfolio spanning imaging and electronics solutions. With a rich history dating back to its founding in 1936, Ricoh has evolved into a leading provider of innovative technologies and services.

Ricoh provides various services, including imaging products, digital transformation solutions, and Additive Manufacturing capabilities. These offerings aim to help organizations improve operations, boost productivity, and achieve sustainable growth. Ricoh prioritizes innovation, utilizing technologies like AI, cloud computing, and IoT to drive competitive advantage. With advanced Additive Manufacturing capabilities, Ricoh facilitates rapid prototyping and customization, transforming traditional manufacturing methods.

With a commitment to sustainability and corporate responsibility, Ricoh actively promotes environmental conservation and social welfare initiatives, striving to minimize its ecological footprint and foster positive societal impact.