The modern engineering market has created a demand for rapid, accurate, and efficient design processes, which has never been higher. At the same time, the evolution of computational design has revolutionized the way engineers create and optimize components, enabling them to transition from concept to production with remarkable speed. At the core of this evolution are two approaches: physics-driven design and data-driven design. Each offers unique advantages and tradeoffs, pushing the boundaries of modern engineering design.

Data-Driven Computational Design

Overview of Data-Driven Design

Data-driven design methodologies focus on using large datasets to inform the design process. By leveraging machine learning algorithms and artificial intelligence (AI), engineers can make predictions, identify trends, and optimize designs based on historical performance data.

Advantages of Data-Driven Design

The main strength of data-driven design lies in its speed, predictive accuracy, and adaptability. AI algorithms can rapidly assess thousands of design possibilities and offer suggestions based on historical data, significantly reducing the time and effort required for manual design iterations.

This adaptability allows engineers to explore a broader range of design alternatives and tailor solutions to meet specific performance criteria, making it especially valuable in industries such as automotive and aerospace.

Limitations of Data-Driven Design

Despite its advantages, data-driven design has limitations. The effectiveness of these methodologies is highly dependent on the quality and availability of data. Without large, comprehensive datasets, the models may struggle to generate accurate predictions, leading to suboptimal designs.

Additionally, the computational intensity required to process these large datasets can slow decision-making, particularly in real-time applications. Moreover, data-driven approaches alone may overlook critical physical constraints, resulting in designs that fail under real-world conditions.

Physics-Driven Computational Design

Introduction to Physics-Driven Design

Physics-driven design operates on a different premise. Instead of relying on historical data, it uses established physics, such as fluid dynamics, thermodynamics, and mechanics, to optimize designs. This ensures that designs meet performance criteria and function reliably in real-world environments. We have developed a solution to automate parts of the design process using advanced topology optimization and physics simulations.

Key Features of Physics-Driven Design

At its core, physics-driven design ensures that solutions are grounded in the realities of the physical world. ToffeeX’s software automates parts of the design process by simulating physical principles, such as heat transfer and material behavior. This results in optimized component designs that meet specific goals, such as reducing material use, improving thermal performance, or enhancing structural integrity.

Our generative design software is effective and adaptable, working across multiple industries, from Aerospace, Energy, Automotive and more. The platform excels particularly in additive manufacturing (3D printing) and supports traditional methods, such as milling and stamping. This flexibility ensures that engineers can create designs tailored to the specific manufacturing process.

Characteristics of Physics-Driven Design

Physics-driven design enables engineers to generate entirely novel geometries—forms that are not limited by historical precedents or existing design data. Because it is grounded in fundamental physical laws, this approach explores the design space freely, identifying optimal topologies based solely on defined goals and constraints.

Unlike data-driven methods, which rely on models trained on existing datasets, physics-driven design can uncover unconventional solutions that have never been manufactured or even imagined before. This not only enhances reliability under real-world conditions but also unlocks performance gains that traditional or precedent-based approaches cannot achieve.

ToffeeX users have reported up to 31% improvements in component thermal efficiency and 3x faster design iterations, demonstrating the transformative potential of this method across various industries, including aerospace, energy, and advanced manufacturing.

Combining Physics-Driven Design and Data-Driven Design

Generative design is a broad and evolving concept, encompassing any process that generates design solutions by iteratively optimizing within specific constraints, whether those constraints are physical, geometrical, or manufacturing-related. In the context of ToffeeX, physics-driven generative design plays a central role in the creation of optimized component designs. The core of this approach lies in physics simulations, which use established laws like fluid dynamics or thermal principles to ensure that the resulting designs are physically viable and perform as expected in real-world environments.

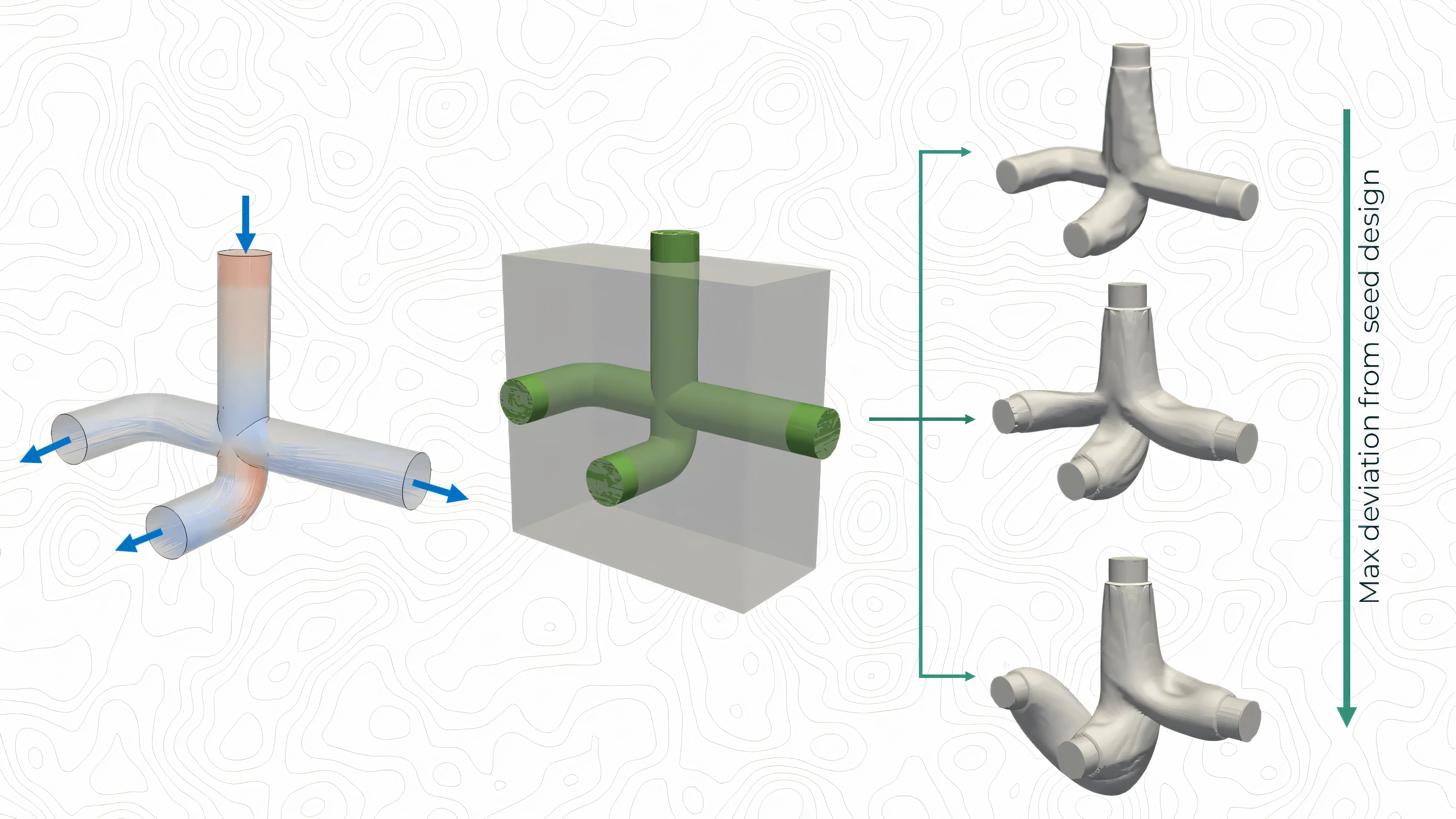

Fluid Topology Optimization

At ToffeeX, topology optimization serves as the backbone of the generative process. It operates within the constraints of the problem’s physics, generating efficient and manufacturable solutions. This method is widely applicable across industries, from aerospace to consumer appliances, as it ensures that designs are inherently robust, grounded in the laws of physics, and ready for production.

However, to fully optimize the design process, ToffeeX also integrates data-driven insights into its generative platform. While physics-driven simulations provide a solid foundation, data-driven approaches leverage machine learning and AI to further refine those designs. This hybrid solution enables the software to capture phenomena specific to certain working conditions or operational environments, such as the extreme demands of aerospace versus the finer tolerances needed for consumer appliances.

For example, ToffeeX uses the same Navier-Stokes equation-based core to optimize components in diverse industries. In aerospace, the software relies heavily on physics-driven methods to ensure reliability under extreme conditions. At the same time, in other sectors, data-driven insights fine-tune the design for efficiency in smaller, less extreme regimes. This combination ensures both generality and precision, producing designs that are optimized by physics and enhanced by data-driven adaptations tailored to specific applications.

Explore Vast Design Spaces

The generative design process within ToffeeX can rapidly explore vast design spaces, optimizing for multiple criteria such as weight reduction, thermal efficiency, or material cost. The hybrid approach ensures that the physics-based optimization keeps designs feasible and manufacturable while data-driven refinements adapt them to meet precise performance needs.

This powerful combination of physics-driven simulations and data-driven refinement makes ToffeeX’s generative design platform a superior tool for engineers seeking both reliability and performance. By marrying the accuracy of physics-driven design with the adaptability of data-driven methods, ToffeeX empowers engineers to create innovative designs more quickly, efficiently, and with greater confidence in their real-world applicability.

Impact on Engineering and Manufacturing

Enhanced Manufacturing with Physics-Driven Design

ToffeeX’s software optimizes designs for their respective manufacturing processes while ensuring efficiency. Whether it’s 3D printing, milling, or stamping, ToffeeX generates designs that consider the specific requirements of each method, minimizing material waste and post-processing time. This results in an earlier start of production (SOP), significant cost savings, and improved production timelines.

Adaptability and Flexibility

ToffeeX’s software is also incredibly flexible, allowing engineers to adapt their designs to various industrial processes. Whether the goal is to optimize for weight reduction in an aerospace application or to enhance thermal performance in a consumer product, ToffeeX offers a solution adaptable to the industry’s specific needs.

Unlocking Practical Intelligence in Design

One of the most powerful shifts in modern engineering is the ability to combine different types of intelligence. By blending physics-driven design and simulation with data-enhanced tools, engineers aren’t just solving problems faster; they’re building smarter systems from the start.

Thermal requirements compete with manufacturability. Cost targets push against performance goals. When these trade-offs surface, engineers need tools that don’t just optimize a single variable, but help them understand how everything fits together. This integrated approach is shaping a new standard, where engineering decisions are not only faster but fundamentally better.